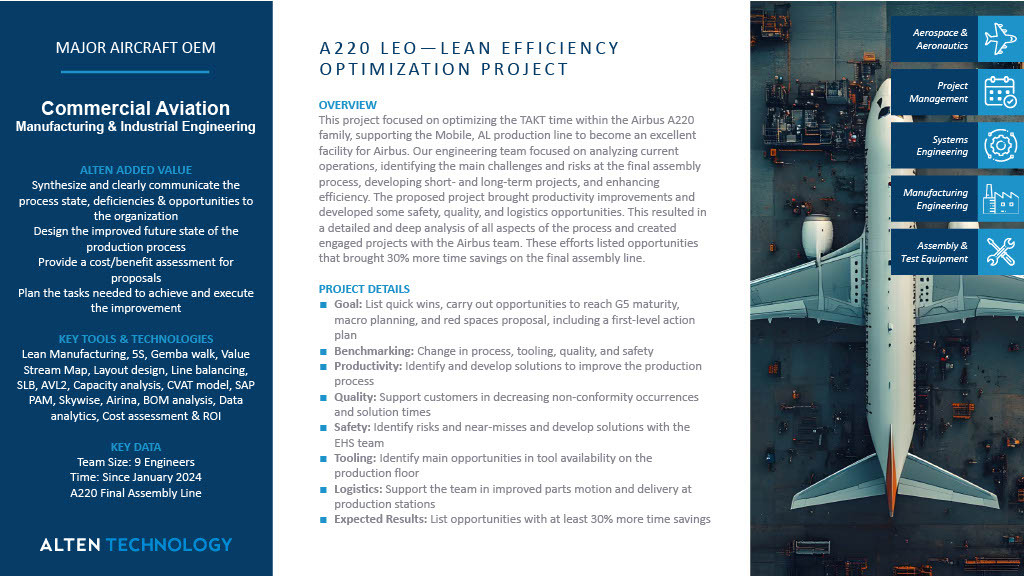

ALTEN was engaged by a major aircraft OEM to optimize TAKT time and production efficiency for the Airbus A220 final assembly line in Mobile, Alabama. The challenge was to enhance throughput while identifying safety, quality, and logistical improvements within a complex, fast-paced manufacturing environment.

The engineering team conducted a comprehensive analysis of current operations, pinpointing bottlenecks and risk areas. They developed both short-term “quick win” solutions and long-term strategic plans aimed at achieving G5 maturity. Areas of focus included macro planning, benchmarking process changes, tooling enhancements, quality control measures, and safety upgrades.

The result was a suite of actionable improvements that led to a 30% increase in time savings on the final assembly line. ALTEN’s collaborative approach and targeted engineering support contributed to transforming the production line into a more efficient and responsive facility, aligning with the client’s performance and scalability goals.